The Future of Energy Management in Smart Factories

Enge Energy, with its solar solutions, energy recovery systems, and smart energy integrations, meets the current needs of factories while preparing them for the future.

As digital transformation accelerates in industry, energy management is undergoing a profound change. Smart factories are using energy sources more effectively to increase efficiency, reduce carbon emissions, and enable sustainable production. At this point, smart energy management systems have become one of the most critical elements shaping the future of manufacturing.

Enge Energy, with its solar solutions, energy recovery systems, and smart energy integrations, meets the current needs of factories while preparing them for the future.

What is a Smart Factory?

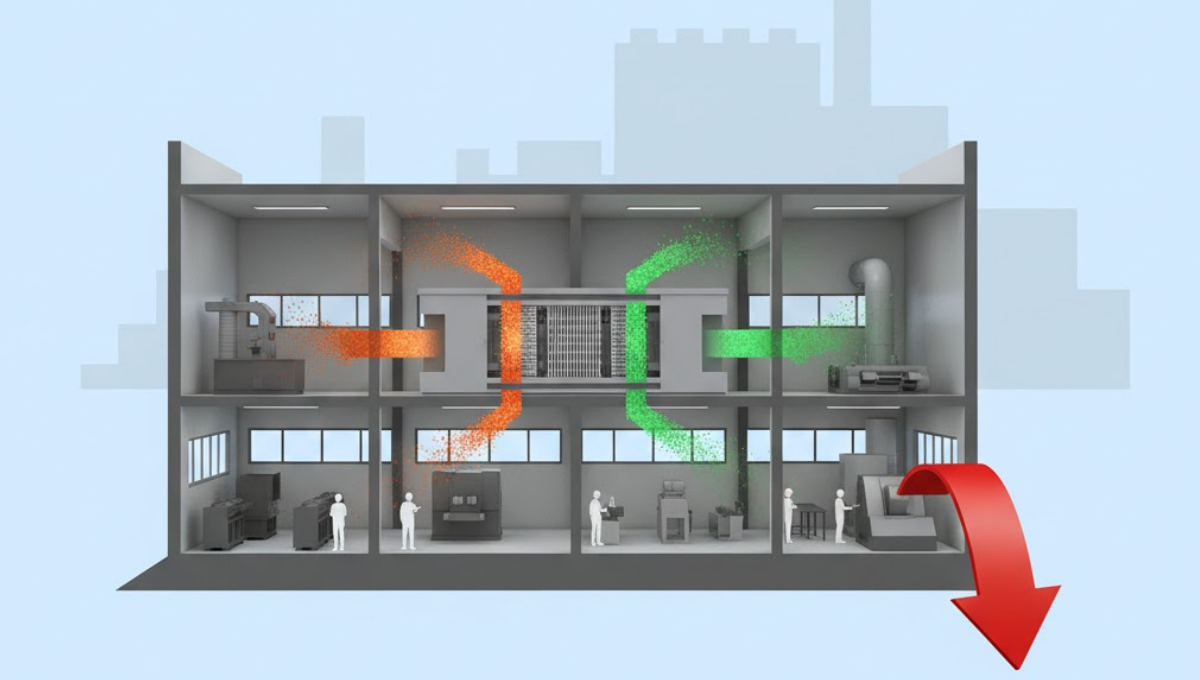

Smart factories are facilities that optimize production processes by using technologies such as the Internet of Things (IoT), artificial intelligence (AI), automation, and big data analytics. Energy management lies at the heart of these systems, as every step in production requires energy.

Key Features of Smart Factories:

- Real-time data collection and analysis

- Instant monitoring of energy consumption

- Recovery of waste energy

- Integration with renewable energy

- Continuous measurement of carbon footprint

The Importance of Energy Management in Smart Factories

Industry accounts for 40% of global energy consumption. Therefore, smart energy management not only reduces costs but also plays a critical role in environmental sustainability.

- Cost Reduction: Minimizes energy losses.

- Carbon Reduction: Enables emission measurement and reduction strategies.

- Efficiency Increase: Provides smart distribution according to energy demand.

- Competitive Advantage: Ensures compliance with regulations such as the Green Deal and carbon taxes.

Technologies Used in Smart Energy Management

1. Real-Time Monitoring with IoT Sensors

Sensors placed throughout the production line, from machinery to building systems, monitor consumption in real time.

2. AI-Powered Forecasting

Artificial intelligence algorithms predict energy demand in advance, based on production intensity and climate conditions.

3. Energy Storage Solutions

Energy obtained from variable sources such as solar and wind is stored in smart batteries and activated when needed.

4. Digital Twin Technology

A digital replica of the factory allows energy scenarios to be tested and the most efficient model identified.

Enge Energy’s Solutions for Smart Factories

Solar heat walls integrated into factory facades meet heating needs naturally and provide energy savings.

Engesolarbox® Technology

Solar drying systems that can be used in production processes increase the use of waste energy and contribute to zero-carbon production.

Waste heat generated in production is recovered through special systems and reused in manufacturing processes.

Smart Energy Integration

Enge Energy’s solutions are integrated with factory systems to minimize energy losses and improve efficiency.

The Future of Energy Management in Smart Factories

Carbon-Free Production Goal

Many countries have pledged net-zero carbon by 2050. Smart energy management will play a key role in achieving this target.

The Green Deal and Regulations

The European Green Deal and carbon taxes make it mandatory for factories to adopt smarter and more sustainable energy management practices.

Fully Integrated Systems

In the future, factories will have digital integration across all processes, from energy consumption to waste management, not just in production.

Conclusion: Factories Ready for the Future

Energy management is one of the most critical elements of smart factories. Enge Energy’s solar-based solutions, energy recovery systems, and smart integration technologies provide major advantages for industries transitioning to low-cost, eco-friendly, and sustainable production.

The factories of the future will not only be smart but also efficient, green, and carbon neutral.

Similar Content