Solar Heat Recovery in Factories

In this article, we will examine how solar heat recovery works in factories, its advantages, application areas, and the technologies offered by Enge Energy.

In this article, we will examine how solar heat recovery works in factories, its advantages, application areas, and the technologies offered by Enge Energy.

Industrial facilities are among the most critical actors in the sustainability agenda due to their high energy consumption and carbon emissions. Electricity, natural gas, and other fossil fuels used in factories not only increase costs but also cause significant environmental damage. At this point, solar-based heat recovery systems emerge as innovative solutions that increase energy efficiency, reduce carbon footprints, and lower production costs.

What is Heat Recovery?

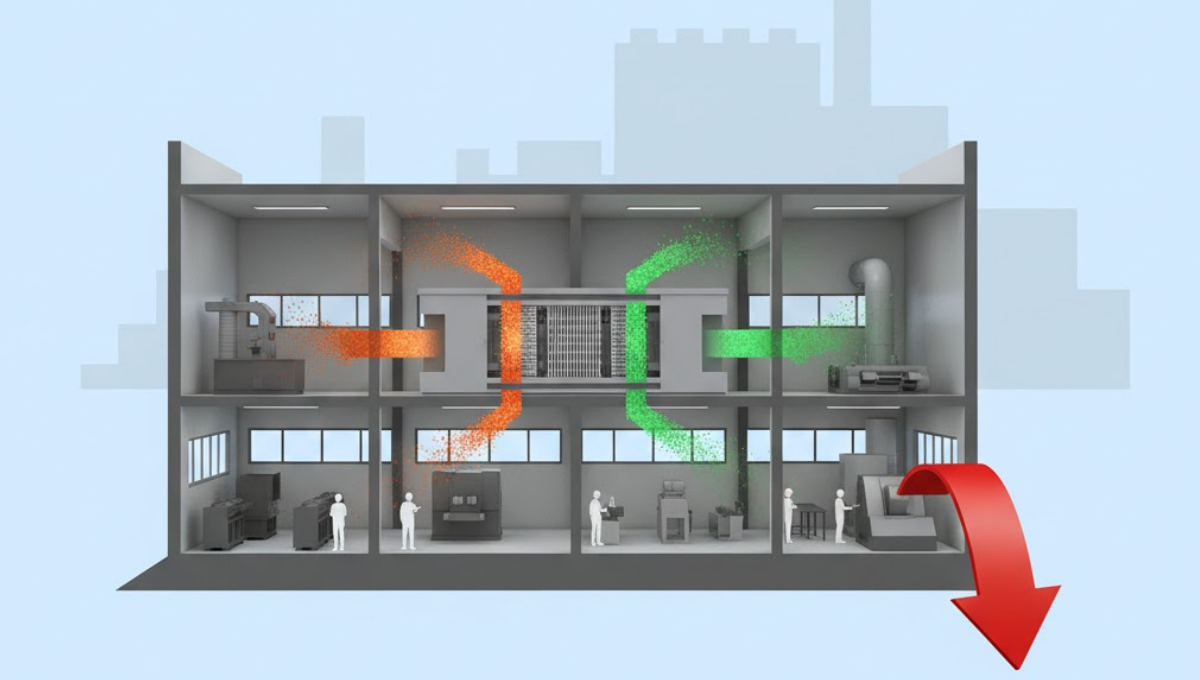

Heat recovery is the process of capturing waste heat generated during production and converting it into reusable energy. Furnaces, dryers, compressors, and HVAC systems in factories produce large amounts of heat, which is often released into the atmosphere and wasted.

Advanced heat recovery systems store this energy and reintegrate it into the production cycle for reuse, thereby reducing both energy consumption and costs.

Solar energy can be utilized in factories for heat recovery in two ways:

- Direct Heating: Solar collectors or panels provide energy for the factory’s heating and production processes.

- Integration with Waste Heat: Waste heat generated in the factory can be reused with solar-assisted systems. Hybrid operation ensures maximum efficiency.

This approach can save up to 30% of annual energy costs in large-scale production facilities.

Advantages of Solar Heat Recovery in Factories

- Economic Benefits

- Lower energy bills.

- Reduced dependence on fossil fuels.

- Short payback period on investments.

- Environmental Contribution

- Reduced carbon emissions.

- Compliance with environmental regulations such as the EU Green Deal and Turkey’s Climate Law.

- Production Efficiency

- Continuity of energy in production processes.

- More stable production environments.

- Corporate Image and Green Certifications

- Easier compliance with ISO 50001 Energy Management Standards.

- Strengthened “green production” image for factories.

Enge Energy Solutions for Heat Recovery

Enge Energy develops innovative systems that integrate solar energy into factory processes.

ENGESOLARBOX® Technology

Solar-powered drying systems, originally designed for food and agricultural products, can be adapted to factories to recover waste heat generated during production.

Used for factory heating and cooling, these pumps operate on renewable energy and recover waste heat back into the system.

Energy Efficiency Consultancy

Enge Energy provides feasibility studies, design, implementation, and energy efficiency reporting for industrial facilities, enabling tailored integrated energy solutions for each factory.

Application Areas

- Food Industry: Drying, sterilization, and packaging lines.

- Textile Factories: Steam and drying processes.

- Chemical and Plastics Sector: Production lines requiring high temperatures.

- Automotive and Metal Processing: Paint ovens and surface treatments.

Customized projects can be designed according to each sector’s waste heat capacity.

Investing in the Future: Solar-Powered Factories

Many factories around the world now meet a significant portion of their energy needs with solar energy. With solar heat recovery:

- Energy costs are minimized.

- Factories move closer to carbon-neutral production.

- Competitive advantage is gained in international markets focused on sustainability.

In Turkey, rising energy costs and stricter environmental regulations make solar-based solutions increasingly inevitable for factories.

Solar heat recovery in factories is one of the most critical technologies for energy efficiency and sustainability. These systems provide both environmental responsibility and cost advantages, driving the industrial sector toward a greener and more efficient future.

Enge Energy, through ENGESOLARBOX® and solar-assisted heat pumps, offers factory-specific solutions, taking a leading role in energy savings and carbon emission reduction.

Actions taken today lay the foundation for a cleaner and more efficient industrial world tomorrow.

Similar Content