How Do Heat Recovery Ventilation Systems Reduce Energy Costs in Factories?

This is where heat recovery ventilation (HRV) systems come into play. Enge Energy’s innovative ENGESOLARBOX® technology enhances these systems with solar energy support — offering industries the possibility of “zero-fuel ventilation.” This article explores how this technology works and how it transforms industrial energy performance.

Energy Efficiency in Industry Is No Longer Optional

With the global rise in energy costs and increasing emphasis on carbon reduction, manufacturing facilities are more focused than ever on energy efficiency.

By optimizing the large amount of energy used for heating and ventilation, factories can significantly reduce operational costs and minimize environmental impact.

This is where heat recovery ventilation (HRV) systems come into play.

Enge Energy’s innovative ENGESOLARBOX® technology enhances these systems with solar energy support — offering industries the possibility of “zero-fuel ventilation.”

This article explores how this technology works and how it transforms industrial energy performance.

What Is Heat Recovery?

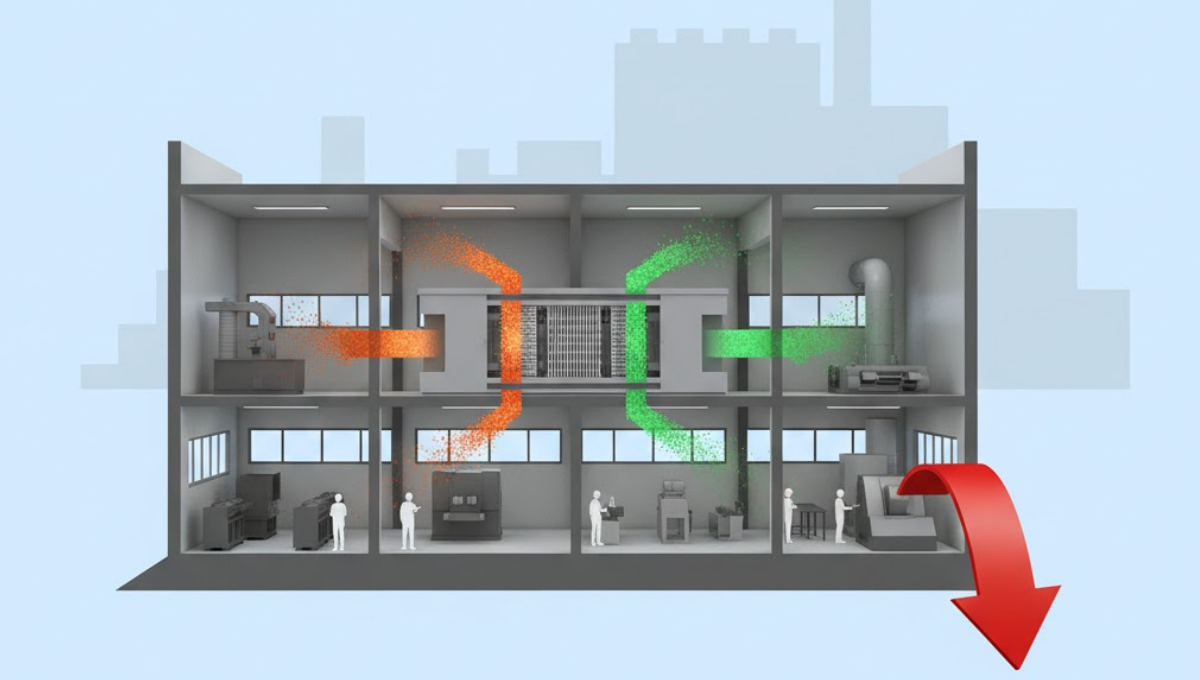

Heat recovery is based on the principle of reusing the heat energy contained in the warm, exhaust air being discharged from a space to preheat the incoming fresh air.

This process recovers a large portion of the outgoing energy — minimizing waste.

In short:

Exhaust air → enters the heat exchanger → transfers its heat → preheats incoming fresh air → provides a comfortable and efficient indoor environment.

ENGESOLARBOX® systems take this process one step further by integrating solar energy as an additional heat source.

Thus, the system utilizes not only waste heat but also solar heat — forming a fully integrated energy recovery system.

ENGESOLARBOX® Technology: Adding Solar Power to Heat Recovery

ENGESOLARBOX® is Enge Energy’s solar air collector technology.

It uses solar energy directly to heat the air and integrates seamlessly into the ventilation system.

System operation:

- Sunlight hits the collector panel surface.

- The special absorber surface converts this energy into heat.

- Warm air is distributed into the factory through air ducts.

- Exhaust air passes through a heat exchanger, transferring its remaining heat back into the system.

This results in fuel-free heating + efficient ventilation + waste heat recovery, all combined in one system.

Benefits of Heat Recovery Systems

1. Energy Savings

In traditional ventilation systems, warm exhaust air leads to major energy losses.

With heat recovery, this loss is minimized — and when solar support is added, savings can reach 60–70%.

2. Improved Workplace Comfort

In winter, cold outdoor air no longer affects employees.

Preheated fresh air maintains a stable indoor temperature, improving comfort and productivity.

3. Reduced Carbon Footprint

For every 1,000 m² of production area, annual CO₂ emissions can be reduced by 20–25 tons compared to conventional systems.

Facilities using ENGESOLARBOX® move closer to achieving carbon-neutral production.

4. Low Maintenance and Operating Costs

There are no burners, chimneys, or boilers as in fuel-based systems.

This reduces maintenance expenses and extends system lifespan.

Application Areas

Solar-assisted heat recovery ventilation systems can be effectively implemented across multiple industrial sectors:

- Textile factories – humidity and temperature control

- Food production facilities – hygienic fresh air requirements

- Plastic and chemical industries – odor and gas extraction

- Warehouses and logistics centers – temperature balance in large spaces

- Assembly lines and production halls

These systems deliver maximum efficiency in large-volume buildings with continuous air circulation needs.

Smart Automation and Monitoring

ENGESOLARBOX® systems are equipped with smart sensors and automation software:

- Real-time monitoring of temperature, humidity, and air quality

- Automatic fan speed adjustment based on outdoor temperature

- Digital energy consumption reporting

- Cloud-based remote access for full control and analysis

This enables real-time, data-driven energy management.

Environmental and Corporate Benefits

Heat recovery systems deliver not only energy savings but also major environmental and corporate sustainability advantages:

- Contribute directly to zero-carbon production goals

- Provide infrastructure compatible with green building certifications (LEED, BREEAM)

- Comply with ESG (Environmental, Social, Governance) standards

- Enhance visibility in corporate sustainability reports

In short, these systems add value to both the environment and the brand.

Technical Comparison – The ENGESOLARBOX® Advantage

|

Feature |

ENGESOLARBOX® Systems |

Conventional Ventilation |

|

Energy Source |

Solar + waste heat |

Natural gas / electricity |

|

Carbon Emissions |

Near zero |

High |

|

Operating Cost |

Very low |

High |

|

Maintenance Need |

Minimal |

Continuous |

|

Efficiency |

80%+ |

50–60% |

|

System Lifespan |

20+ years |

10–12 years |

The Era of Zero-Fuel Energy in Factories Has Begun

Energy efficiency is no longer a choice — it’s a strategic necessity that provides a competitive edge.

ENGESOLARBOX® Heat Recovery Ventilation Systems lower energy costs while enabling environmentally conscious production.

With these systems, businesses:

- Consume less energy,

- Create more comfortable work environments,

- Produce for a cleaner and more sustainable future.

Join Enge Energy in the era of Zero Fuel – Zero Waste – Zero Carbon.

Similar Content